What Is Stud Welding

Stud welding is a fast, reliable and accurate method of welding a metal fastener to another metal object. The resultant weld joint is stronger than the stud or parent material. Improved product design is achieved since reverse marking is eliminated and the area around the stud is flat and clean.

In order to weld the stud, access is only required from one side which means that component handling is reduced. Welds are also leakproof and tamper proof, and since no holes are punched in the sheet, corrosion problems are reduced and the work piece is not weakened.

Stud welding can also be used on single sided pre-coated polished or painted materials. The fastener can be made from many metals or alloys.

Stud welding benefits:

Fast attachment. No reverse marking. The welded joint is stronger than the parent material or the stud. Access is only required from one side. No holes hence no leaking or weakening of the sheet. Tamperproof. Pre-coated or painted materials can be welded. The equipment is portable and easily jigged. In fact Stud welding overcomes all of the disadvantages of the following problems.

Problems with Alternative Fixing and Fastening Methods

Drilling and Tapping:

These processes are very slow. Thicker parent material and longer studs are required.

Inserts:

They can eventually work loose. They can crack paint and leave unsightly stains. Holes need to be deburred in parent material. The reverse side is not always clean and flat. The parent material is weakened by holes.

Back Welding:

The process is slow. Holes need to be punched and deburred in parent material. The excess weld needs grinding off for a clean flat finish. The parent material is weakened by holes.

Through Bolting:

Requires two handed assembly and access from both sides. Holes need to be punches and deburred in parent material. Bolt heads are unsightly and stains can come from the bolt holes. The assembly is not leakproof and the parent material is weakened by the presence of holes.

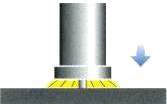

Capacitor Discharge "CD" Welding Processes

The capacitors are charged to a pre-set voltage to suit the diameter to be welded. The stud pip is placed into contact with the sheet.

Upon triggering, the stored energy is discharged as a high current pulse, melting the pip and producing an arc.

Return spring pressure forges the stud into the molten surface area on the sheet to give complete fusion across the flange.

| Stud/Material/Power | Advantages | |

|---|---|---|

| Designed specifically for thin gauge materials where reverse marking must be minimal. Sheet surface should be clean and flat. Stud has a weld pip. | Stud Diameter 1mm - M10 |

Low cost equipment, low cost studs, fast to load and weld, easy to jig and automate, small light equipment, no ferrules or shrouding gas required, good weld results with aluminium or brass in addition to mild and stainless steel. Weld is clean and requires no finishing |

| Material Thickness 0.7mm & above |

||

| Power Requirements Single Phase 240/110 Volt |

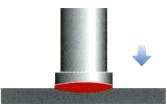

Drawn Arc "DA" Welding Processes

Current and weld time is pre-set to suit the diameter to be welded. The stud is then placed on the plate

Upon triggering, a pilot arc occurs as the stud lifts to a pre-set height.

The main arc then melts the weld end of the stud and creates a molten pool in the plate

Return spring pressure forges the stud into the molten pool. The ferrule contains the molten metal and shapes the fillet

| Stud/Material/Power | Advantages | |

|---|---|---|

| Very strong penetrative welds are achieved with this process. Ferrules required to contain and shape molten metal. Weld end of stud is fluxed. | Stud Diameter 3mm to 30mm |

Burns through parent material laminations, tolerates surface curvature and imperfections e.g. light rust, scale, grease and some coatings. Gives neat and controlled weld fillet. The only method of stud welding large diameters. This process also lends itself to multi-gun applications. |

| Material Thickness 2mm & above |

||

| Power Requirements Three Phase 415 Volt |

Short Cycle "SC" Welding Processes

This process is the same as for Drawn Arc, but operates over a much shorter time period - up to 100 milliseconds. Ceramic arc shields (ferrules) are not required with this process, but shrouding with gas can improve weld fillet formation especially when welding stainless steel studs. Capacitor Discharge studs may be used.

| Stud/Material/Power | Advantages | |

|---|---|---|

| More penetrative welds than CD and is suitable for hot rolled/coated materials. | Stud Diameter M3 to M8 |

This process is more tolerant than CD of uneven or dirty surfaces. Can be easily automated and can utilise low cost CD studs. Ferrules are not required, however shrouding gas improves weld spatter |

| Material Thickness 1.5mm & above |

||

| Power Requirements Three Phase 415 Volt |

Advanced Studwelding Systems

We are an independent, ISO 9001:2015 Quality Approved Supplier for all your stud welding requirements